Quality Hawa Enterprises Sanforize Rubber Belt

HAWA ENTERPRISES the most reputed name in the line of Rubber Belt technology applied to the controlled compressive fabric shrinking process of the Zero-Zero machines.

HAWA ENTERPRISES the most reputed name in the line of Rubber Belt technology applied to the controlled compressive fabric shrinking process of the Zero-Zero machines.

HAWA ENTERPRISES' Zero-Zero Rubber Belt normally used in textile finishing process (properly known as sanforizing) for pre-shrinking fine, lightweight cloth and can also be used for twills, drills and other medium weight fabrics.

The success of the HAWA ENTERPRISES Rubber Belt is due to, not only to it’s time proven quality, but also to the prompt technical service provided to customers. This value added service provided by qualified multi-lingual staff gives HAWA ENTERPRISES customers confidence to compete in all world markets and to command the best prices for their goods.

HAWA ENTERPRISES Rubber Belt are manufactured using highest quality raw materials and ingredients which are often available only with a very high priced Rubber product manufacturer. The time proven “ply built” method ensures absolute Rubber Belt surface uniformity, ideal rubber dynamics for maximum cloth pre-shrinking capacity throughout Rubber Belt useful life, and uniform performance throughout belt thickness from beginning to end.

HAWA ENTERPRISES' efforts towards gaining technical superiority by perseverance and innovation, earning product loyalty by consistent supply, unfailing service, maintenance and single-minded dedication, fulfilling the stringent demands of the textile industry has always stood the company in good stead. Ever striving for a 'Zero-Defect' product performance, Hawa Enterprises today are able to assure a production of nearly 10 million meters of sanforized cloth subject to excellent conditions maintaining the Zero-Zero Rubber Belts.

More than 1000's of satisfied HAWA ENTERPRISES customers, return to HAWA ENTERPRISES time after time for the unequalled Rubber Belt quality and unique technical support.

Hawa Zero Rubber Belt Available Sizes:

| Machine type | Shrinking Range | comfit |

|---|---|---|

| Internal Circumference (mm) |

962 | 962 |

| Thickness (mm) |

50 to 71 | 50 to 55 |

| Width (mm)Structure |

1200 to 2100 | 1200 to 2100 |

| Surface hardness (ShA) |

39OC | 39OC |

| Temperature resistance | 90OC-140OC | 90OC-140OC |

Textile Zero Sanforize Belt:

Hawa's Compressive shrinkage Rubber Belt is used to remove shrinkage of all types of fabrics. It is produced from highest quality, dirt free natural rubber and selective quality polymers to give very high compressive strength to the product. This ensures a non-sticky surface for excellent fabrics finish during shrinkage process of textile. The composition of Hawa's Rubber Belt enables extensive fabrics processing trail in Indian as well as world conditions. The high quality speciality rubber additive and high performance anti-degradants have been selected to prevent surface degradation of Rubber Belt at high temperature processing which gives excellent heat resistance and superior flex life to product.

The Rubber Belt is built on specially designed machine by skilled trained staff to give blister free product and vulcanized under controlled temperature conditions. The Rubber Belt is carefully surface ground on precision specially designed grinding machine to give smooth surface finish required for fabrics processing.

Hawa's superior quality Belt can be easily processed at high steam pressure on modern high speed machines to give shrinkage free fabrics. Because Hawa's superior heat resistance product quality gives uninterrupted service before stopping the machine for grinding the fresh smooth surface. The good abrasive surface and excellent flex quality of the Rubber Belt is expected to give atleast 10 to 15% higher meterage of fabric under ideal processing conditions than other brands of Zero Rubber Belt available in Indian market and therefore Hawa's Zero Rubber Belt is most cost competitive. Due to lower stoppage of sanforize machine for fresh surface grinding of Belt and fine surface finish after grinding, Hawa's Zero Belt has now became "First Choice" in Textile Industry.

Principles Of Zero Finish:

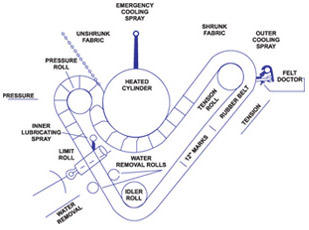

We explain below the compressive shrinkage principles of Rubber Belt :

The Simplest way of illustrating the principles involved in controlled Compressive Shrinking is to take a piece of Rubber and bend it as shown in Fig 1. A piece of fabric is then laid on the convex surface and held by each finger and thumb. As the Rubber is allowed to straighten, it will be seen that the length of the fabric exceeds the length of rubber, forming a loop of fabric as shown in Fig 2. This is the surplus fabric available for Compressive Shrinkage by mechanical means.

The conditioned fabric is fed on to the Rubber Belt unit at point 'A' and held firmly. At point 'B' where the Rubber Belt changes its shape from Convex to Concave, there will be a surplus of fabric, which is progressively and smoothly compressed between points 'C' and 'D'

This is a very versatile range with ability to shrink mechanically fabrics varying from light weight poplins to heaviest suiting materials up to 18%. Fabrics processed on this machine will be zero shrunk, based on the CCCT 191. A wash test with a tolerance of +1%

Technical Specification for Rubber Belt:

Hardness: The recommended Hardness of Rubber Belt is between 36 degree to 39 degree shore 'A' depending on fabrics to be processed.

Hardness: The recommended Hardness of Rubber Belt is between 36 degree to 39 degree shore 'A' depending on fabrics to be processed.

Width: Hawa Enterprises offer current width 2000 mm. Normally Rubber Belt should be 150 mm to 200 mm wider than the cloth to be processed.

Circumference: The standard internal circumference of Belt 3962mm (13 feet)

Thickness: The most common thickness of Rubber Belt is 67 mm (2.5/8") and varies upto 70mm. Higher thickness will initially require higher force for outer surface elongation as the belt turns around the pressure. This result in cracks on outer surface and will need to grind surface frequently and will often rubbing of the Rubber Belt from inner surface.

Normally Rubber Belt thickness depends on the shrinkage needed in fabrics being processed. For processing light weight fabrics with low shrinkage fabrics such as poplins, fancy prints & synthetics dress material etc, Belt thickness of 55 mm is recommends this belt will have shrinkage capacity 5-8% For processing heavy weight fabrics like Denims, Twill, Drills etc. thickness Belt of 67-71 mm is recommended. The Belt has maximum shrinkage capacity Upto 15% for light weight fabrics processed on comfit type machine 50 mm. Thick belt is most suitable with 3-5% shrinkage of fabric.

Request for Quote

Quality Control

The Simplest way to illustrating the principles invollved in controlled Compressive Shrinking is to take a piece of Rubber and Blend

The Simplest way to illustrating the principles invollved in controlled Compressive Shrinking is to take a piece of Rubber and Blend

More ››