Packing & Storage of Rubber Belt

Hawa Enterprises uses a special Design wooden box which will maintain its circular shape. The Belt is dusted with fine talc powder and wrapped in hessein cloth to prevent any surface damage. The wooden box is lined with corrugated paper to protect Belt from sunlight, heat & dust particles. To remove belt from Box, remove the two side planks provided with removable bolts. Insert metal Pipe and lift the Belt from carefully with the help of pulley chain. Remove the Hassein cloth from Belt packing only before installation. The Belt should be stored away from sunlight or heat source in a cool & dark place & should be protected from contact with oil, grease & solvent to prevent from deterioration of rubber.

Hawa Enterprises uses a special Design wooden box which will maintain its circular shape. The Belt is dusted with fine talc powder and wrapped in hessein cloth to prevent any surface damage. The wooden box is lined with corrugated paper to protect Belt from sunlight, heat & dust particles. To remove belt from Box, remove the two side planks provided with removable bolts. Insert metal Pipe and lift the Belt from carefully with the help of pulley chain. Remove the Hassein cloth from Belt packing only before installation. The Belt should be stored away from sunlight or heat source in a cool & dark place & should be protected from contact with oil, grease & solvent to prevent from deterioration of rubber.

Keep away the Belt from electrical devices, electrical running motor & high tension field which is a source of generation of ozone which destroys rubber surface faster.

If Belt is stored for more than 10-12 weeks before use then it should be turned it upside down after one week removal from box to prevent it from permanent set deformation at one end. Then again turned upside after a week before use.

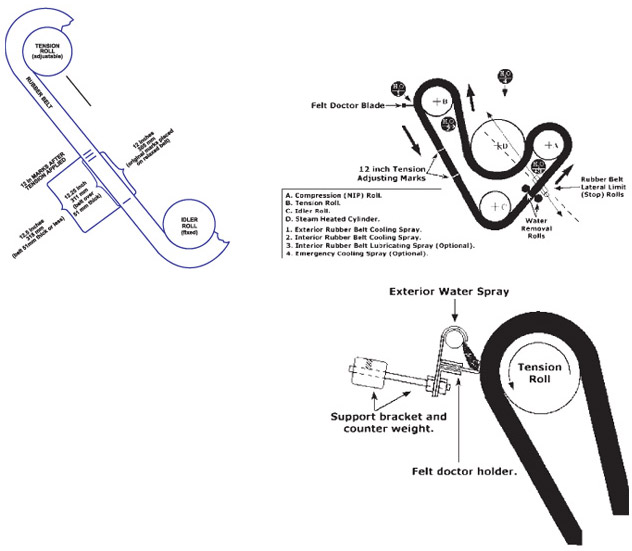

Installation of Rubber Belt:

After removal of the used belt from machine, Inspect the central heating cylinder, pressure rollers & its bearing for smooth running. Remove any scale deposited on the central heating cylinder. The surface of all pressure rolls/ drums should be properly cleaned & should be free from any rough edges. Remove hessein cloth form the Belt & clean the talc powder with cloth. The floor near the machine should be spread with some cloth so that the Belt will not pick up any dirt or spilled near the machine. Mount the belt smoothly.

After mounting the Belt, set all pressure and squeeze rollers in low tension and run machine empty initially at lower speed to remove set developed in Belt before use. Set the central heating drum at proper steam pressure and spray the Belt with water continuously on both surfaces out side & inside also.

The Belt should stretch as follow:

- For 67 - 71 mm thickness stretch only 2.5%

- For 50 - 57 mm thickness stretch only 4 %

Higher stretching will lead to surface crack development and poor life of the Belt. At each edge of the Belt draw a test line 12 inches (300 mm) length is drawn as guide line so that extend of stretching can be controlled on both sides. e.g. extension of line from 300 mm to 308 mm to 313 mm allow to rotate Belt under stretched condition before determination of total stretch. After mounting the Belt on machine buff the surface lightly, before initial use.

Request for Quote

Quality Control

The Simplest way to illustrating the principles invollved in controlled Compressive Shrinking is to take a piece of Rubber and Blend

The Simplest way to illustrating the principles invollved in controlled Compressive Shrinking is to take a piece of Rubber and Blend

More ››